ZUGFeRD 2.2 import for Dynamics 365 for Finance

ZUGFeRD (Zentraler User Guide des Forums elektronische Rechnung Deutschland) is an e-invoicing format combining a human-readable PDF/A-3 and an embedded XML file using the CII (Cross-Industry Invoice) syntax. The CII syntax may also be used in the xRechnung, which is a pure XML version of the German e-Invoice. From 2025, the ability to receive and process electronic invoices becomes mandatory for B2B transactions in Germany.

Microsoft’s current solution in Dynamics 365 for Finance provides support specifically for the UBL (Universal Business Language) format of the xRechnung: Import vendor electronic invoices – Finance | Dynamics 365 | Microsoft Learn. It enables the import of vendor invoices received in this format, mapping them as pending vendor invoices in D365. The invoice may be uploaded directly into the system or placed in a SharePoint folder for unattended processing.

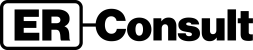

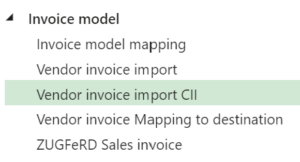

We are happy to announce the release of the CII (Cross-Industry Invoice) dialect of the xRechnung / ZUGFeRD electronic invoice. This solution is implemented via Electronic Reporting (ER) configurations, which means it does not require any customisations and can be easily installed across all active versions of D365. It sits on top of the standard Invoice model v280, Vendor Invoice Mapping to Destination v280.46, side by side with the configuration Vendor Invoice Import v280.7.

We are happy to announce the release of the CII (Cross-Industry Invoice) dialect of the xRechnung / ZUGFeRD electronic invoice. This solution is implemented via Electronic Reporting (ER) configurations, which means it does not require any customisations and can be easily installed across all active versions of D365. It sits on top of the standard Invoice model v280, Vendor Invoice Mapping to Destination v280.46, side by side with the configuration Vendor Invoice Import v280.7.

The functionality aligns with the standard Microsoft UBL import, utilizing the key data elements for processing and ensuring PO matching:

- Header: Invoice ID, Invoice date, Due date, Vendor ID, Currency code, and a header-level note.

- Lines: Line number, Item ID, Quantity, Sales unit of measure, Sales price, Discount (percentage discounts are converted to absolute values as the XML schema doesn’t support percentages), Price unit, Name, Description, and Line amount (excluding VAT).

The solution supports the ZUGFeRD 2.2/Factur-X 1.0 profile EN 16931, also known as the “COMFORT” profile (being also a subset of the EXTENDED profile), which meets all tax law requirements and must be accepted by customers unless explicitly denied.

Price

| Version | Price | Deliverables | Notes |

| Light | €890 | The Vendor invoice import CII Electronic Reporting configuration | This option does not require any X++ customisations or 3rd party software and can be installed and used right away. |

| Light+ | €1200 | Same as the Light version but with 5 hours of prepaid support and installation |

Your can acquire the solution on the official Microsoft AppSource marketplace: ZUGFeRD CII import (microsoft.com)

Setup and use

- Follow the steps outlined in the Microsoft’s guidance Import vendor electronic invoices – Finance | Dynamics 365 | Microsoft Learn:

- Import the same three configurations from Microsoft (Prerequisites);

- Import the configuration Vendor invoice import CII.xml provided to you;

- Open Accounts payable > Setup > Accounts payable parameters; on the Electronic documents tab, select the imported Vendor invoice import CII format.

- To run either one of the formats – UBL or CII – by choice, you may download and import a complimentary X++ extension with an additional parameter CII vendor invoice and an own menu item underneath the standard one: VendImportInvoice_CII.axpp. In the batch execution mode this does not matter, because each of the formats becomes its own Electronic source with a set of SharePoint folders etc.

- Prepare the master data: make sure the vendors are stored with proper VAT numbers in Dynamics 365 for Finance.

- Make sure that the vendor’s external item ID mapping exists. Any Buyer Assigned ID (our item number) potentially sent by the vendor is neglected by the Microsoft’s mapping, and the conversion to the internal Item ID is always handled via the external item IDs. Under these conditions, the import works as expected and the PO lines may be matched.

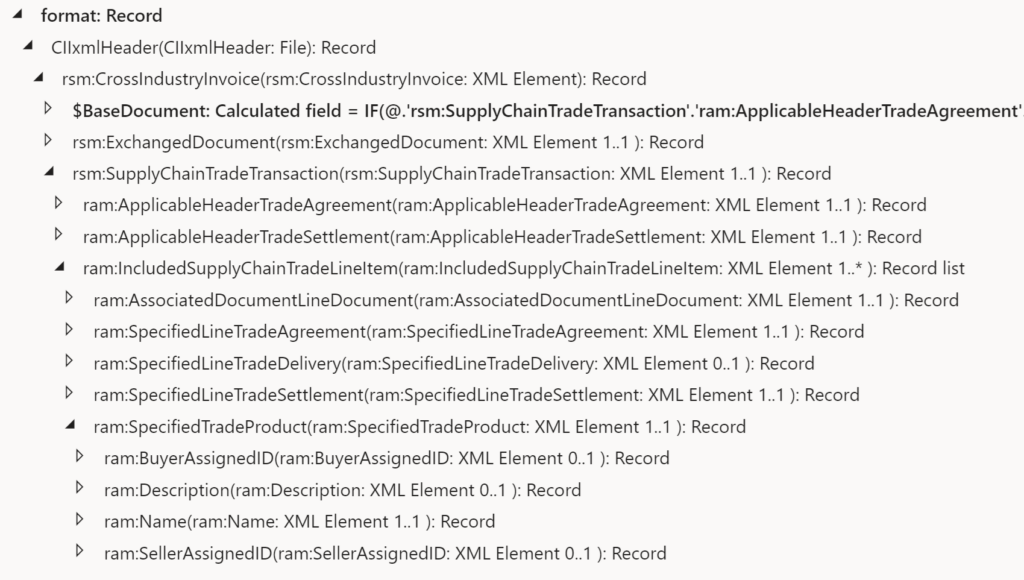

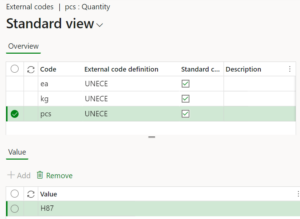

Make sure that the units of measure are properly mapped to the UNECE Recommendation No. 20 list called “Codes for Units of Measure Used in International Trade”. E.q. the UNECE unit H87 must be mapped to either PCS or EA or STK.

Make sure that the units of measure are properly mapped to the UNECE Recommendation No. 20 list called “Codes for Units of Measure Used in International Trade”. E.q. the UNECE unit H87 must be mapped to either PCS or EA or STK.- Perform an interactive test upload by using the function Accounts payable > Periodic tasks > Import vendor invoices (or Import CII vendor invoices if you installed and configured the above extension from step 5). Beware: contrary to the UBL format, the CII (“COMFORT”) invoice does not include any line-by-line reference to the purchase order lines. Just the PO number is sent in the header. We assume that the numeration of the invoice lines mostly follows the PO lines numeration. If not, the standard mapping will fall back to the matching by the line purchase price.

- Configure the batch mode with Electronic sources as outlined in the guidance at step 1.

Useful links

- End user license agreement: ZUGfERD_Import_EULA

- You may download sample invoices here: ZUGFeRD 2.3 | Forum elektronische Rechnung Deutschland (ferd-net.de). To extract an XML attachment suitable for the import, you may use Adobe Reader or Adobe Acrobat.

- A rich interactive ZUGFeRD schema navigator is hosted here: EN 16931 – FacturX 1.03 – ZUGFeRD 2.0.1 – COMFORT (gefeg.com)

E-invoice and configurable business documents blog series

Further reading:

Aktueller Stand der eRechnung in D365 for Finance (Deutschland)

Austrian Peppol-UBL e-invoice

ZUGFeRD 2.2/ Factur-X 1.0 for Dynamics 365 FO

How NOT to send an order confirmation per e-mail

Enumerate lines in Configurable Business Documents

Canvas sections in D365 Configurable Business Documents

Electronic reporting: Italian eInvoicing FatturaPA, CIG and CUP numbers, RIBA

Italian eInvoicing FatturaPA: Part 2