Towards the deconsolidation in Dynamics Warehouse Management

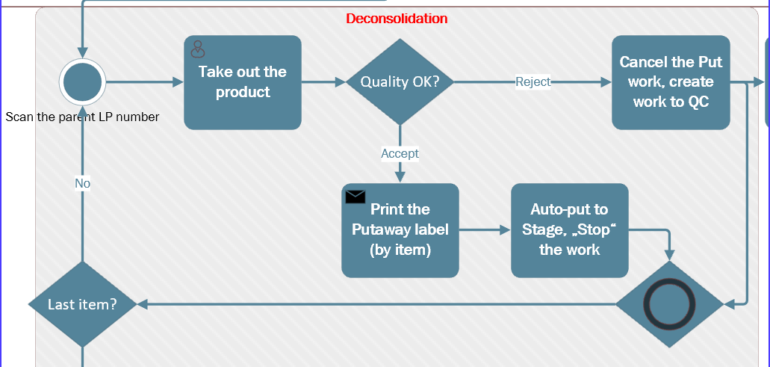

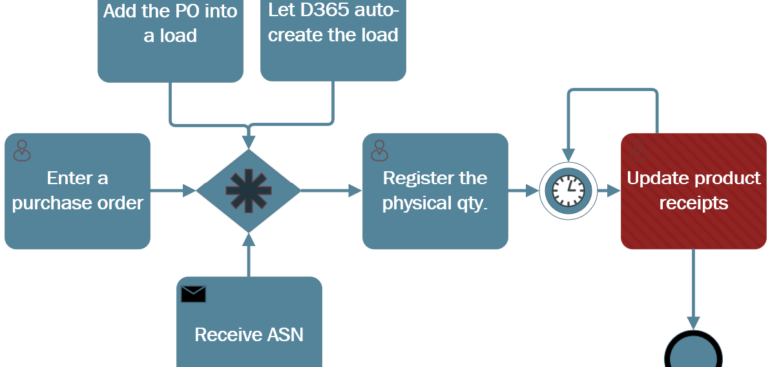

The deconsolidation (opening of a complex packaging, quality control, taking small packages out of the larger packages announced by the supplier of the goods via ASN) seems to be a well-established process in SAP EWM, yet the implementation in Dynamics for SCM, its WHS module may turn cumbersome. Below is the workflow one may configure in Dynamics WHS out of the box:

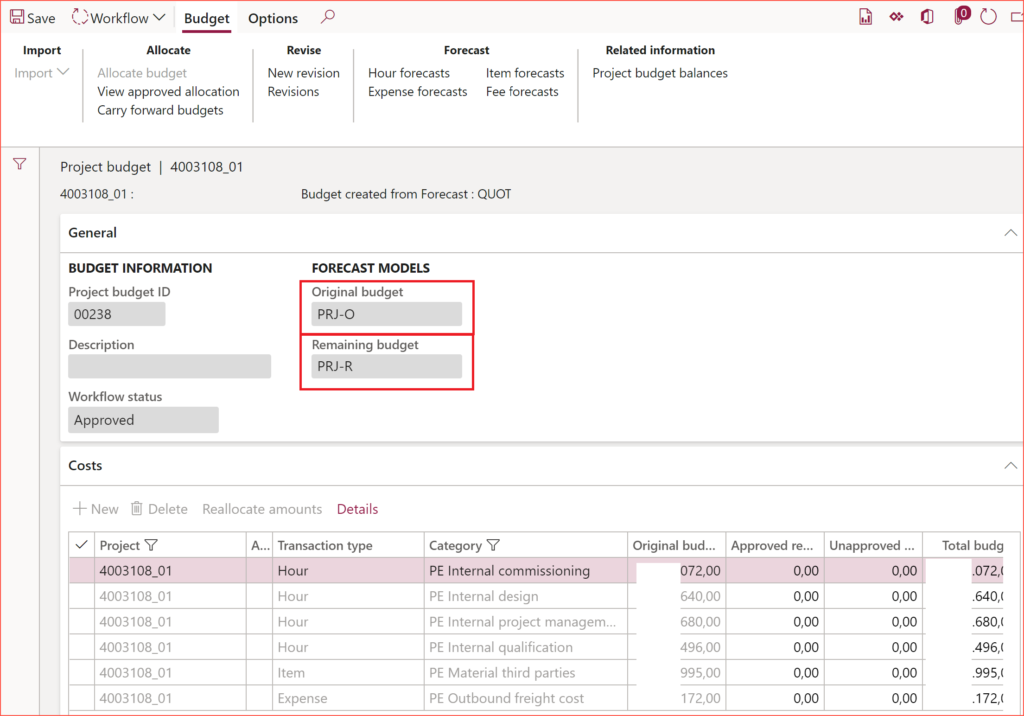

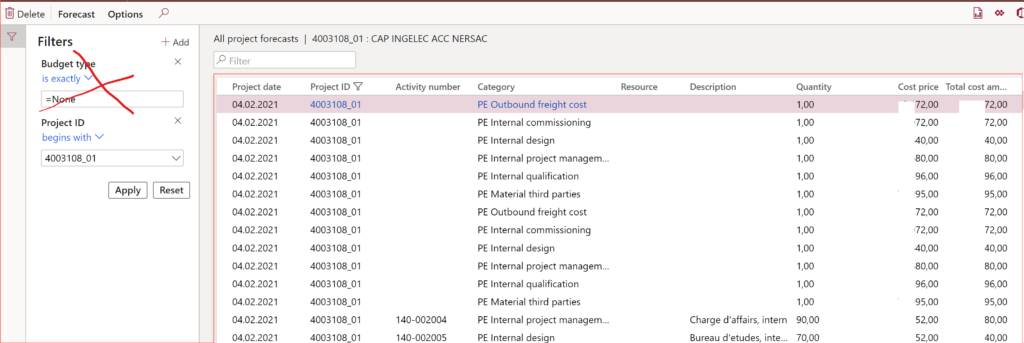

It all begins with an Advance Shipping Notice transmission and import. The invaluable – and only available – source on this topic is located here: Processing of inbound ASNs in Warehouse Management in AX ‘7’ (kashperuk.blogspot.com). The ASN creates an inbound load and a packing structure for a Purchase Order in Dynamics. I identified 2 distinct scenarios:

- Multi-SKU: The packing structure contains multiple items in one single box (or on one pallet). Here one needs to understand that the Import project in Dynamics Data management must still be “pre-conditioned” with an XML file containing nested cases (boxes) and all 6 entities in the composite entity “Inbound ASN” even though the real message will not be using either the WHSInboundLoadPackingStructureCaseEntity (representing the nested license plates i.e. packing structure cases) nor the WHSInboundLoadPackingStructureCaseLineV2Entity (the one with the items in the packing case). My file for the pre-conditioning is here: InboundASN_ASNEntityConditioning, while the real message can be stripped down to 4 entities

the load Id

… the purchase order(s) in that load

…… the parent license plate(s)

……… the content of the license plate - Multi-case: the ASN contains a packing structure (max. 1 level of depth) where the boxes (packing cases) are on the Parent License plate (i.e. pallet or master box), and the multiple items are in their own cases (boxes). An example is here: InboundASN_NestedLPCase. Let’s state one thing straight: the process does not work in this scenario. Let’s explore, why.

Nested LP (multi case) scenario

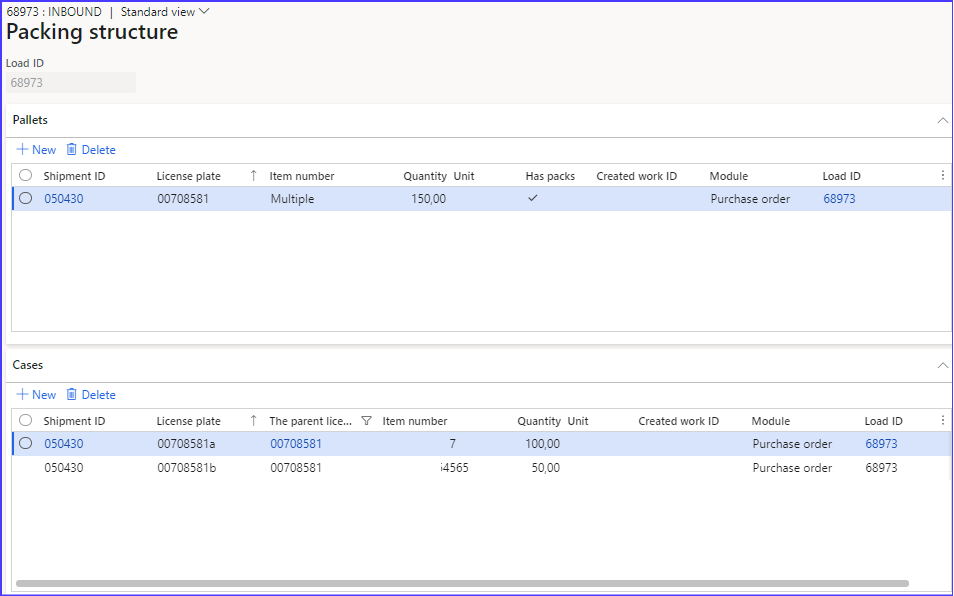

Once the ASN has been imported, navigate to Warehouse management > Loads > Open loads, then open Ship and receive / Packing structure:

The cases (aka nested license plates) 00708581a and 00708581b are on the parent license plate 00708581 and contain the items. Use the Mobile menu item License plate receiving to process this ASN. It displays the list of the items and let the parent and the nested license plates emerge at the default receipt location (here: DOOR). The system registers the parent and the nested LPs all right, but the stock of the items is on the parent LP only!

This fundamental flaw in Dynamics is well documented here: License plate receiving via the Warehouse Management mobile app and therefore becomes a ‘feature’, not a ‘bug’

This action culminates in an “insufficient on-hand” error, because the moment you receive the parent LP, it generates the put-away work and reserves the whole freshly received quantity for the same. The stock cannot be moved (because this is what the Pack to nested license plates really does: creates a series of movements between the parent and the nested licence plates).

The typical approach is to let the put-away work be omitted with a Work policy, or be automatically performed for the stock to stay at some logical staging location right after the receipt. The split nested LPs are then distributed into the main storage with a Movement by template menu item. However, a movement by template does not support either the Disposition codes or the Quality management (Quality management for warehouse processes – Supply Chain Management), because both the QC methods are only allowed for purchase orders and production orders, not the movements. This essentially rules out the standard WHS quality control.

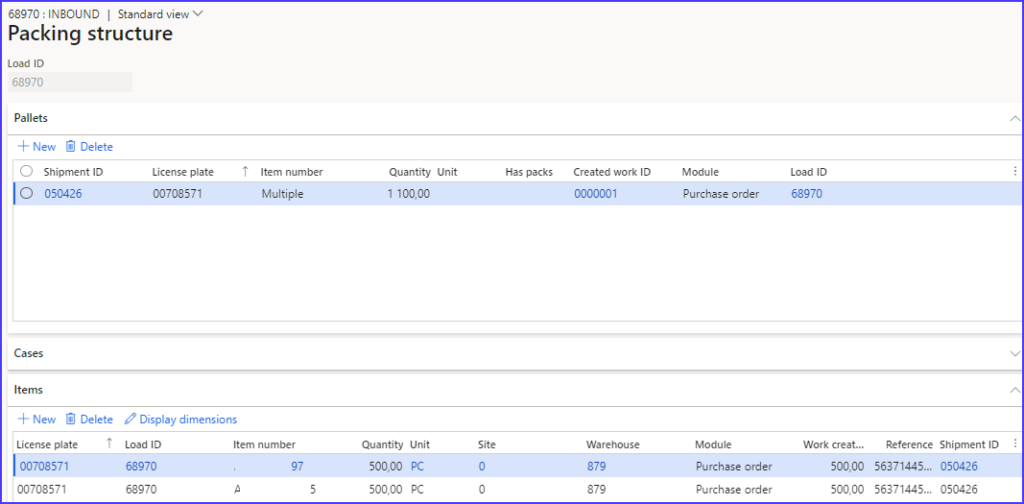

The only viable solution is to elevate the cases to parent LPs in the ASN interface, i.e. to convert nested cases to multiple “parents” of their own. This effectively reduces the nested-LP scenario to a multi-parent, multi-SKU one:

Multi-SKU scenario

The list of the Cases in the Packing structure is empty now; instead, one or many parent license plates contain one or many items each:

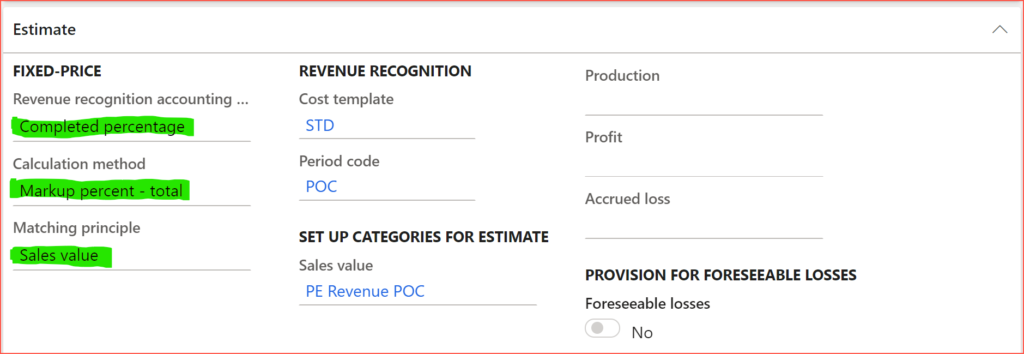

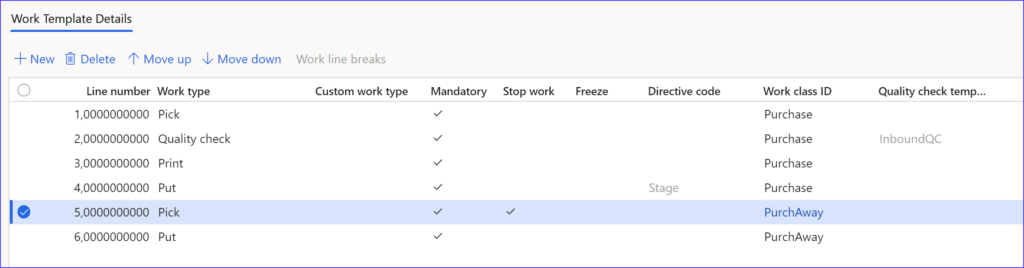

Now, the secret of the proper work processing, deconsolidation and the proper location determination is the staged Work template for the purchase order receiving process:

Location DOOR → DECO → Final BIN or bulk location

The DOOR location is considered the staging area before the deconsolidation, while the DECO location (injected by the Directive code = Stage in the work template / location directive) is the staging area after the deconsolidation where the put-away work is sorted and clustered for further processing:

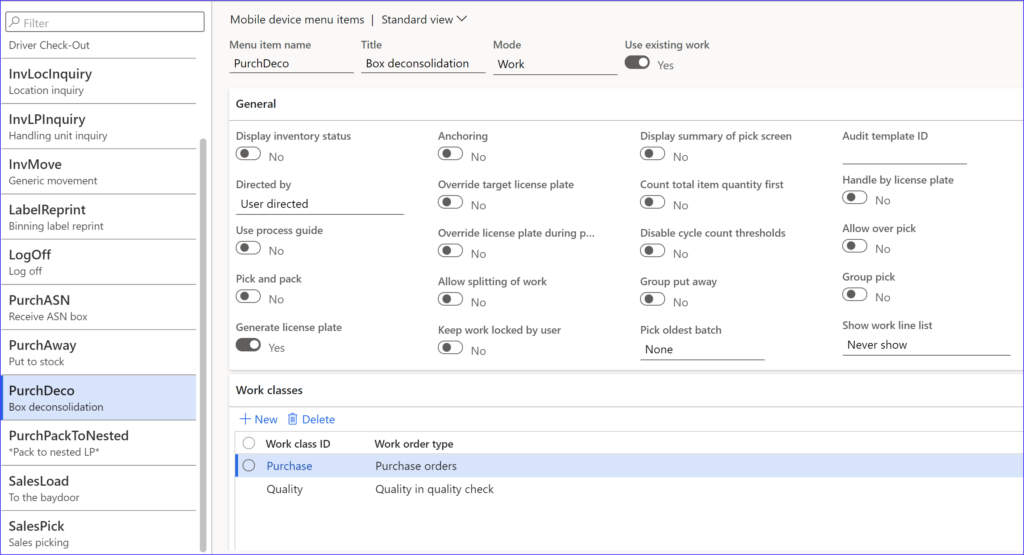

The process needs 3 mobile menu items: License plate receiving – Work (one Work class ID) – Work (another class ID).

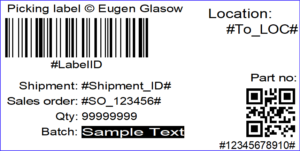

The Print work type here substitutes the Print checkbox on the menu item, because the latter is printed earlier when the parent LP is at the DOOR while it is considered a Multi-SKU license plate: it is going to be printed only once and the item number and the location are going to be empty. Also note the Stop work break after the deconsolidation part (lines 1-4) to interrupt the flow at the DECO staging location and transfer the duties from one warehouse team to another.

The second piece of the puzzle is the Work header break by the Item number: it will create as many work headers as there are items, all for the same parent LP, with a unique final Put location each. This location is nicely printed on the label, along with the Item ID, i.e. we have successfully reduced a Multi-SKU case to a single-SKU one to locate a unique bin by item.

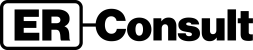

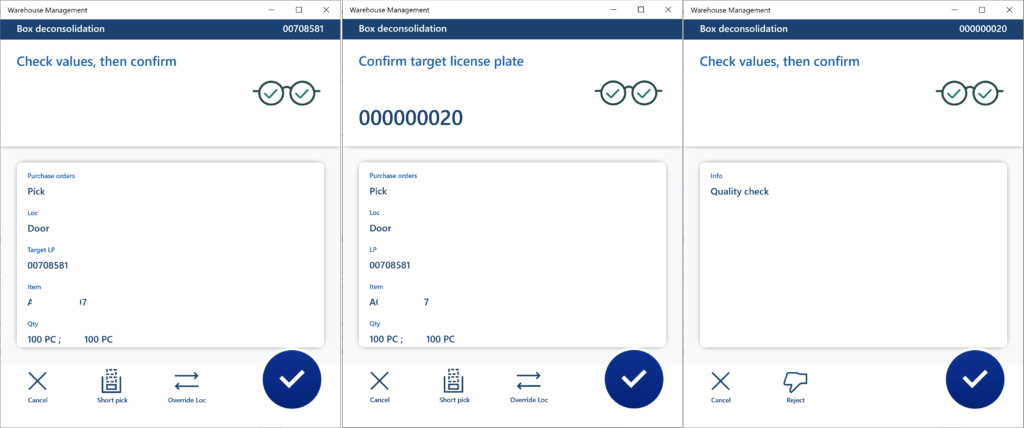

At the deconsolidation station, the same parent LP is scanned over and over again and it randomly directs to the next open purchase work = item to be taken out from the parent LP. A quality control is nicely tied in (however, the ASN quantity as a whole may be either accepted or rejected; a single damaged piece may only be split in a separate movement process at a QC location if fully rejected first):

The last piece of the puzzle is the Generate license plate option at the menu item for the purchase work processing:

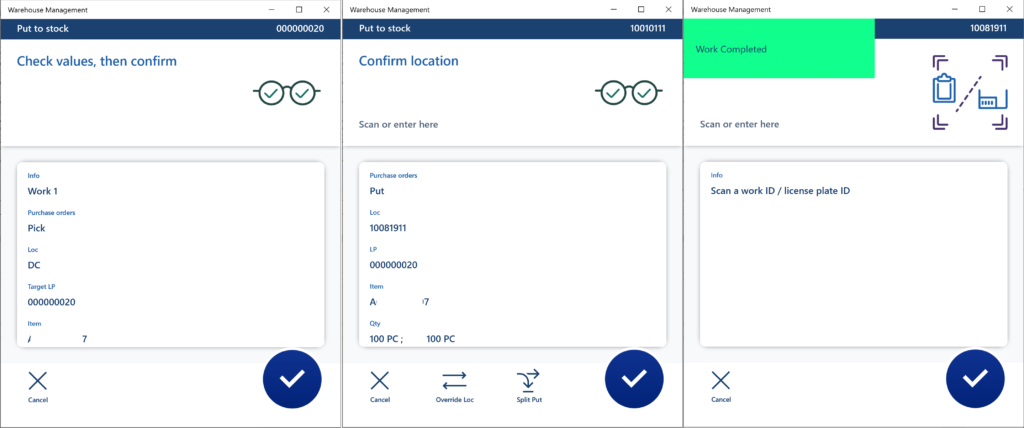

It replaces the ambiguous Parent LP number with a fresh unambiguous LP number (see the Confirm target license plate step above). The same is used by the “put-away people” to initiate the final movement into the destination bin / bulk location (lines 5-6 in the Work template):

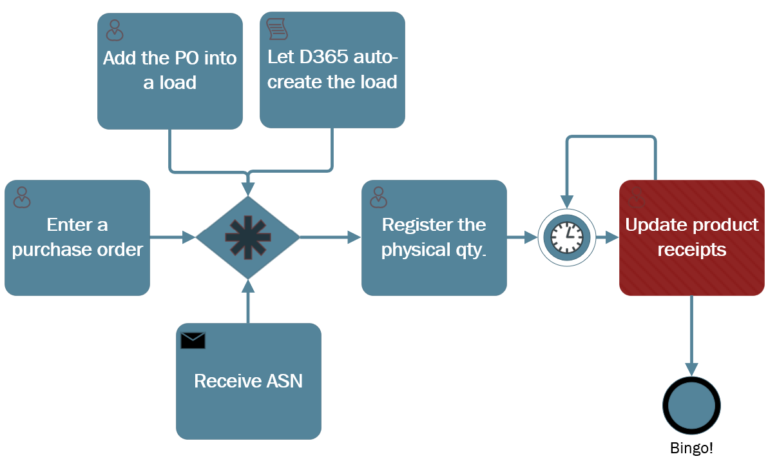

Bingo!

The last trick may be a batch job (Warehouse management > Periodic tasks > Change inventory status) updating the Inventory status from Inbound to Available in every bin, bulk, floor location every 2 minutes. The reason is a potentially early reservation of the goods in the receiving / staging locations while the quality inspection might not yet have taken place. The sales order location directives consider the regular bin/bulk/floor locations only, and the reservation in the receiving area results in an empty Pick location in the outbound work.

Use the configuration from by blog Dynamics 365 SCM: Do not reserve in Inbound to force the non-reserveable inventory Inbound status upon all purchase orders.

Warehouse management blog series

Dissecting the Warehouse Management app layout

Dynamics 365 SCM: Do not reserve in Inbound

Bye-bye work report, welcome wave labels!

WHS Label copies, Custom work, display methods on labels

Towards the deconsolidation in Dynamics Warehouse Management

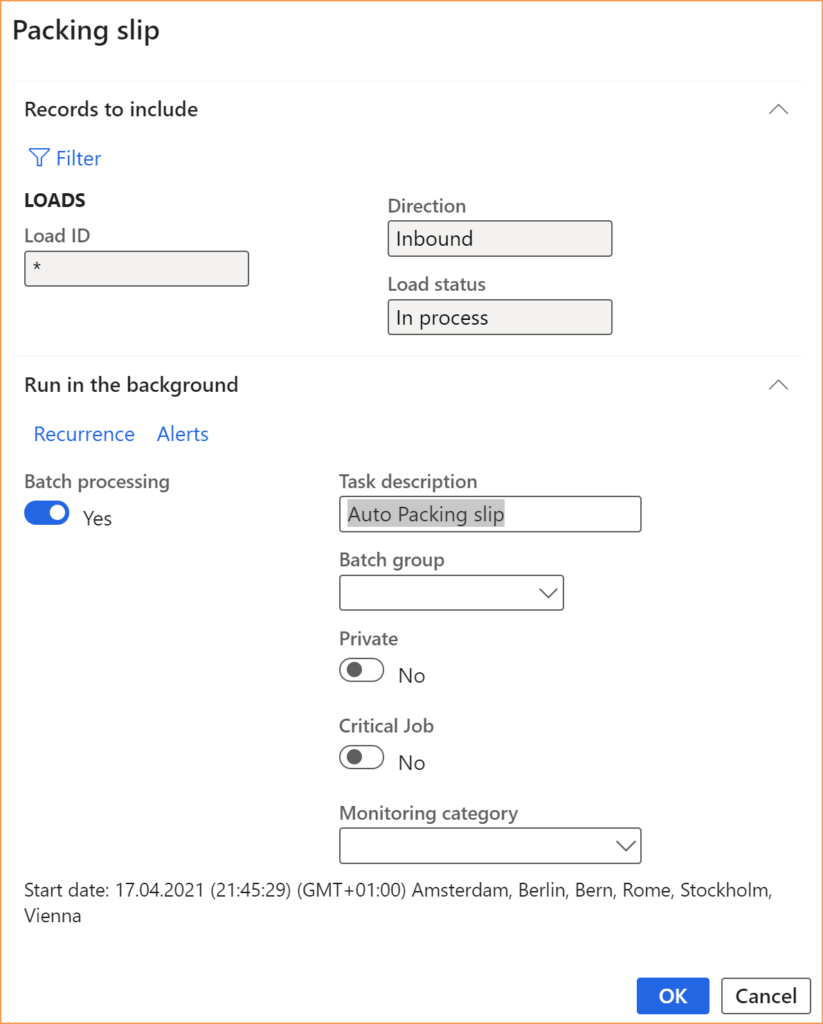

Auto-post inbound delivery notes in a batch

Input validation and messaging in the Process Guide Framework

WHS Emulator screen in Dynamics 365