Auto-post inbound delivery notes in a batch

- Eugen Glasow

- April 17, 2021

- 8:49 pm

- No Comments

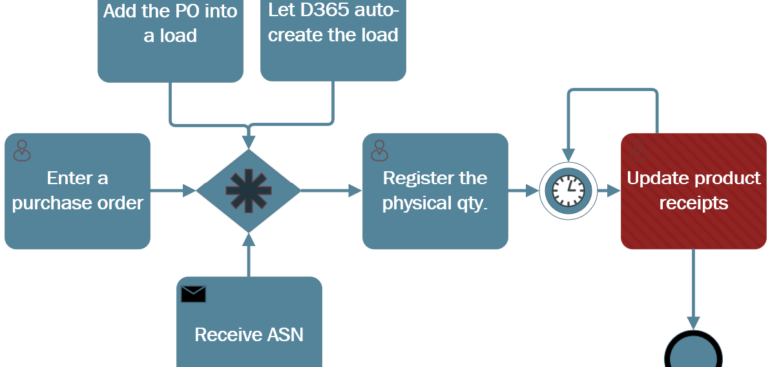

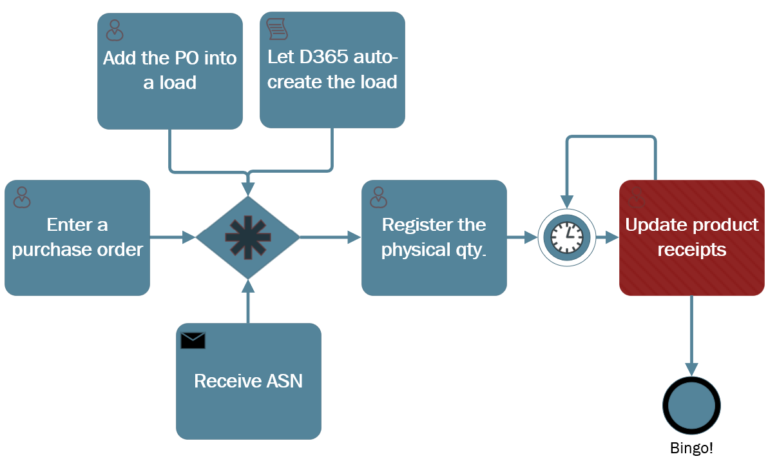

In order to register a manual or an OCR purchase invoice, the accountant should match the quantity against the delivery notes (en-us: packing slip) captured at the warehouse. But what if the inbound area is only equipped with mobile scanners? What if we do not have the carbon copy on hand, or just don’t care about the printed document at all? The shipment may be damaged or incomplete! Indeed, we should only pay for what we’ve physically received:

Register the actual quantity → Post the ‘Product receipt’ with that quantity → Match the invoice against the same → Claim the difference from the supplier, if any.

However, when registering the said delivery note against the purchase order with the Generate / Product receipt button or the respective periodic task, the user must provide the delivery note number as written by the supplier of the goods. This makes an automation with a batch job at the first glance impossible, because it requires human interaction.

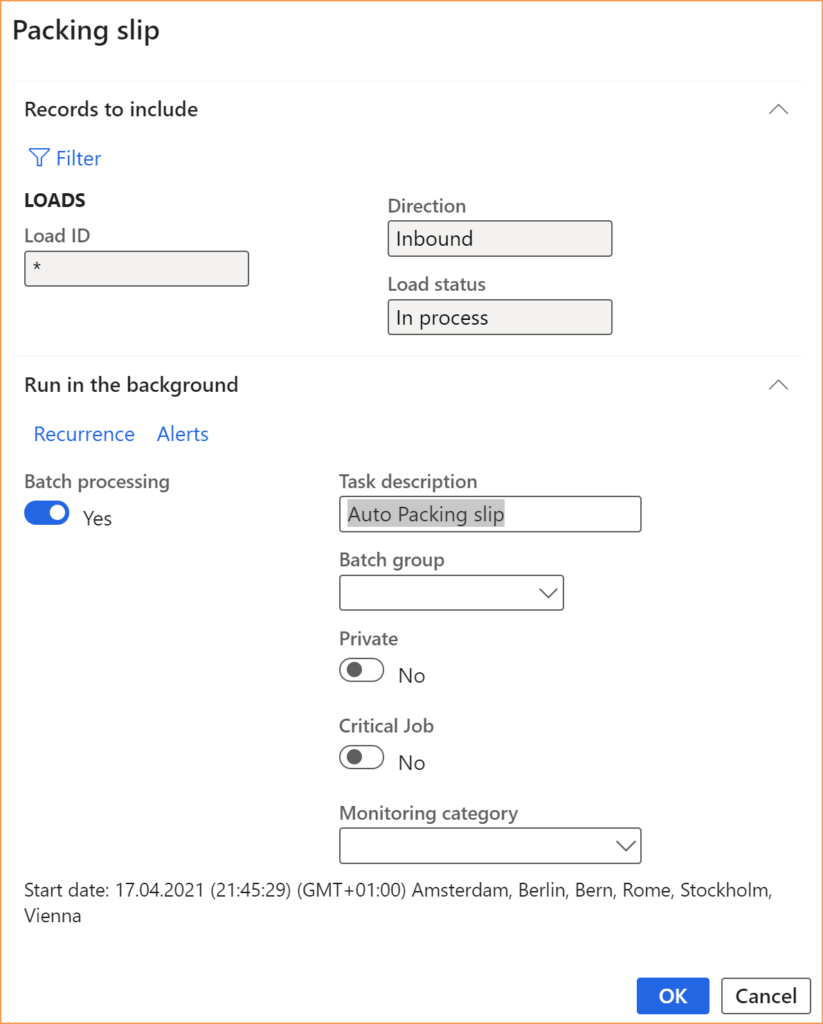

Update product receipts

The automatic job Warehouse management / Periodic tasks / Update product receipts is the remedy. For every inbound load within the given constraints, it creates and posts a delivery note aka packing slip with the total registered quantity.

The inbound load does not necessary require any active management. The load may be…

- Created manually out of the purchase order lines in the Load planning workbench

- Imported from an ASN, but also

- Added by the system automatically if the parameter Automatically create at purchase order entry is turned on

If the load is not confirmed, the Update product receipts will confirm it automatically first, then promote to the final status Received. The bogus delivery note number is like LOADID_N, where N is a running number. The quantity is the registered quantity versus the respective load line(s). It does not matter how the registration came about:

- Mobile scanner PO line/item receiving or PO line/item receiving and put away

- Mobile scanner License plate receiving or License plate receiving and put away [against an ASN]

- Mobile scanner Load item receiving or Load item receiving and put away

- Mobile scanner Mixed license plate receiving or Mixed license plate receiving and put away

- the new simplified License plate receiving: license-plate-receiving-enhancements

- the classic inventory Arrival journal

- and last but not least, the classic Registration at the purchase order line level.

In essence, you just scan the last pallet of the PO and forget. At the end of the working day (or faster, depending on the batch job schedule) the system will process every In process load (i.e. where the receipt of at least one pallet has started) and make as many delivery notes as needed to update the purchase orders.

More on inbound loads

The only limitation is the use of the advanced Warehouse management processes at the warehouse, i.e. the inbound load may only be created at a WHS-enabled warehouse. More on inbound load handing here: https://docs.microsoft.com/en-us/dynamics365/supply-chain/warehousing/inbound-load-handling.

The recent features “Associate purchase order inventory transactions with load” and “Multiple product receipt postings per load” may be beneficial.

Warehouse management blog series

Dynamics 365 SCM: Do not reserve in Inbound

Bye-bye work report, welcome wave labels!

WHS Label copies, Custom work, display methods on labels

Towards the deconsolidation in Dynamics Warehouse Management

Auto-post inbound delivery notes in a batch

Input validation and messaging in the Process Guide Framework

WHS Emulator screen in Dynamics 365